The production of new energy vehicles requires higher quality compressed air

The automobile manufacturing industry is a large consumer of compressed air. Whether it is stamping, welding, purging, manipulator driving, or painting and assembly, compressors are required to provide compressed air power. With the emphasis on the environment and the requirements for carbon emissions, in addition to traditional fuel vehicles, new energy vehicles have accelerated into our side.

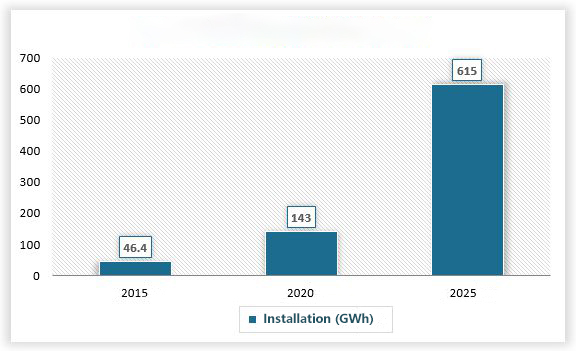

New energy vehicles, represented by electric vehicles, have also developed most rapidly. With the continuous breakthrough and progress of technology, electric vehicles have been continuously optimized and developed in mileage, reliability and cost. In addition, the state's subsidies to the new energy vehicle industry are still strong: the purchase tax exemption, free license plate and other policies will continue to be implemented, so it is estimated that the growth rate of the new energy vehicle industry will reach 79% in 2022.

The new energy electric vehicle mainly focuses on the battery, motor and electronic control. As the power source of the whole system, the battery is regarded as an important technology for the development of electric vehicles, accounting for about 30% of the vehicle cost. The performance of the battery is also directly related to the length of the vehicle's mileage.

In the manufacturing process of new energy vehicles, in addition to the above conventional gas consumption links, air compressors also generate demand in lithium and nickel mining and processing, power battery production, chip production and other links. In the production process of power battery, it is necessary to ensure that the compressed air can meet the strict requirements of each process. Pure oil-free air compressor is required for power battery production. As the post-processing equipment of compressed air power, dryer plays a very important role. Dryers are required to provide high-quality dry compressed air for cleaning, coating, painting assistance and automatic stamping. For example, zero air consumption compression heat adsorption dryer, micro air consumption blowing heat adsorption dryer, combined dryer, module dryer and other equipment, select a high-quality dryer to ensure that the compressed air is dry, clean and free of impurities, and provide reliable compressed air for the safe production of new energy vehicles.

JOY MACHINERY always adheres to the corporate vision of "building a leading brand of oil-free air compressors in the world", and hopes to provide high-quality, clean and safe air for food, beverage and other production enterprises on the road of oil-free air compressor research and development, production and sales. Source protection, and also contribute a little bit to people's health and safety.

JOY MACHINERY oil-free air compressor series is widely used in the food and beverage processing industry due to its clean air source and continuous and stable gas transmission. If you have any needs, please contact us! JOY Machinery (Shanghai) Co., Ltd. has a professional design team with rich experience and welcomes customization. Diversified products can meet most applications and meet your one-stop shopping needs. The air compressor series includes power frequency screw air compressors, variable frequency screw air compressors, permanent magnet variable frequency screw air compressors, two-stage compression screw air compressors, integrated screw air compressors, laser cutting air compressors, medium and high pressure air compressors. Air compressors, oil-free water-lubricated screw air compressors (special oil-free screw air compressors for the medical industry), diesel-moving screw air compressors, electric-moving screw air compressors and other products.

"Customer satisfaction is our unswerving pursuit", "High quality, good services", and strive to make every customer use the good products they like.

For more information about our products, please visit us at : www.wriol.cn, 24-hour hotline: 13621925718 (WeChat, WhatsApp).