What are the benefits of water lubricated screw air compressors?

With the development of society, the advancement of technology, and the improvement of living standards, the devices we use around us are also quietly changing. From the popularity of micro-oil air compressors, to now more and more related to people's livelihood or important industries, oil lubricated air compressors are gradually replaced, which is also the trend of the times, JOY Machinery ( The editor of Shanghai) Co., Ltd. will introduce to you as follows:

The water-lubricated oil-free screw air compressor is automatically replenished through system control. The water tank will repeatedly replace the water in the air end of the water-lubricated oil-free screw air compressor, so how does the water-lubricated oil-free screw air compressor automatically replenish water?

The water replenishment is not performed at one time. Without affecting the work of the water-lubricated screw air compressor head, the water replenishment is carried out periodically, and the time interval of the water replenishment can be set.

Compared with other forms of oil-free air compressors, oil-free water-lubricated screw air compressors have significant advantages:

1. Water is used as the compression sealing and cooling medium, and the operating cost is extremely low.

2. After advanced sealing and blocking technology, the compressed air is cleaner and can be pure and oil-free.

3. While water is used as lubrication, it can easily carry particles, dust, etc. in the compressed air to make the compressed air cleaner.

4. Higher volumetric efficiency and more energy-saving, more than 15% energy saving than the secondary dry twin-screw, and more than 36% energy saving than the first-level dry twin-screw.

5. Avoid frequent problems and high maintenance costs of the dry screw machine, making it more stable and reliable.

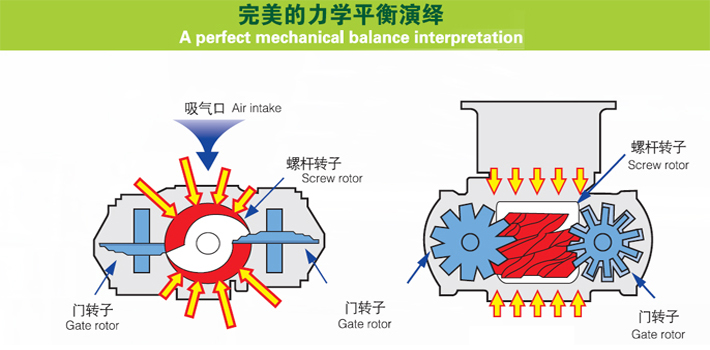

6. Lower noise, the axial and radial forces of the single screw are balanced, and the star wheel body rotates freely with the screw under the smooth water film, so the main engine parts run smoothly under low load, ensuring low noise and durability.

7. Compared with traditional air compressors, it saves consumables such as lubricating oil, oil filter and oil and gas separation core, and then reduces maintenance and protection costs (calculated in one year, it is roughly 1/5 of the protection cost of traditional micro-oil air compressors) .

8. No oil, then use more environmentally friendly.