Working principle of air compressor

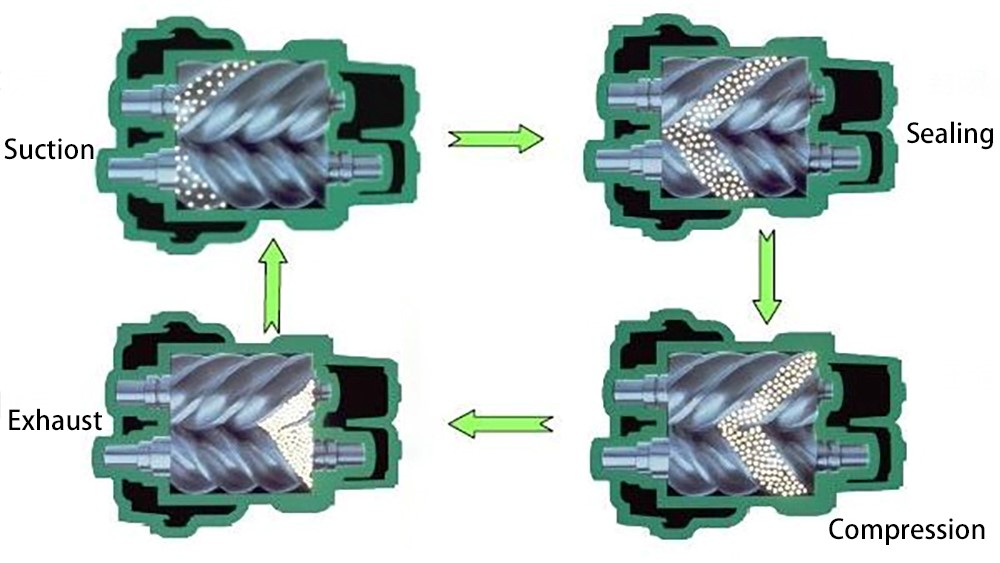

The whole screw air compressor works in four processes. They are suction, sealing, compression and exhaust.

1. Inspiratory process:

The intake port on the intake side of the screw air compressor is designed to make the compression chamber fully inhale, and the intake is only regulated by the opening and closing of the intake regulated valve. When the rotors rotate, the main (male) and auxiliary (female) rotors have the largest space when they turn to the inlet end wall opening. At this time, the rotor slot space is connected with the free air at the air inlet. Because the air in the slot is completely discharged during the exhaust, the slot is in a vacuum state when the exhaust is finished. When they turn to the air inlet, the outside air is inhaled and flows into the slot of the rotor axially. When the air fills the entire slot, With the rotation of the rotors, the tooth surface of the male rotor and the tooth slot of the female rotor begin to mesh and gradually complete until the air between the mesh line and the tooth slot is closed.

2. Sealing and conveying process:

At the end of suction, the main and auxiliary rotors are sealed with the casing at the teeth of the main and auxiliary rotors. At this time, the air is closed in the teeth groove and no longer flows out, that is [sealing process]. The two rotors continue to rotate, their tooth peaks and grooves coincide at the suction end, and the mating surface gradually moves towards the exhaust end. This is the [conveying process]

3. Compression and injection process:

In conveying process, the meshing surface gradually moves towards the exhaust end, that is, the gap between the meshing surface and the exhaust port gradually decreases, the air in the gap is gradually compressed, and the pressure increases, that is, [compression process]. At the same time, the lubricated oil is also injected into the compression chamber and mixed with the chamber gas due to the pressure difference. This is the [injection process].

4 Exhaust process:

When the meshing end face of the rotor is turned to be connected with the casing exhaust port, the compressed air pressure reaches the maximum, and the compressed air begins to exhaust until the meshing surface of the tooth peak and the tooth groove moves to the exhaust end face. At this time, the space between the meshing surface of the two rotors and the casing exhaust port is zero, that is, the [exhaust process] is completed. At this time, the length of the tooth groove between the meshing surface of the rotor and the casing air inlet reaches the maximum, and the suction process is in progress.

JOY MACHINERY always adheres to the corporate vision of "building a leading brand of oil-free air compressors in the world", and hopes to provide high-quality, clean and safe air for food, beverage and other production enterprises on the road of oil-free air compressor research and development, production and sales. Source protection, and also contribute a little bit to people's health and safety.

JOY MACHINERY oil-free air compressor series is widely used in the food and beverage processing industry due to its clean air source and continuous and stable gas transmission. If you have any needs, please contact us! JOY Machinery (Shanghai) Co., Ltd. has a professional design team with rich experience and welcomes customization. Diversified products can meet most applications and meet your one-stop shopping needs. The air compressor series includes power frequency screw air compressors, variable frequency screw air compressors, permanent magnet variable frequency screw air compressors, two-stage compression screw air compressors, integrated screw air compressors, laser cutting air compressors, medium and high pressure air compressors. Air compressors, oil-free water-lubricated screw air compressors (special oil-free screw air compressors for the medical industry), diesel-moving screw air compressors, electric-moving screw air compressors and other products.

"Customer satisfaction is our unswerving pursuit", "High quality, good services", and strive to make every customer use the good products they like.

For more information about our products, please visit us at : www.sh-joymachinery.com; www.wriol.cn , 24-hour hotline: 0086 13621925718 (WeChat, WhatsApp).