The Interpretation National Compulsory Energy Efficiency Standards - "Energy Efficiency Limits and Levels for Electric Motors"

On June 1, 2020, the newly revised national standard "Energy Efficiency Limits and Energy Efficiency Grades for Electric Motors" (GB18613-2020) was officially released. This standard revision integrates two mandatory energy efficiency standards, namely GB 18613-2012 "Energy Efficiency Limits and Energy Efficiency Grades for Small and Medium sized Three Phase Asynchronous Motors" and GB25958-2010 "Energy Efficiency Limits and Energy Efficiency Grades for Small Power Motors", and is planned to be implemented from June 1, 2021.

Electric motors are widely used in the industrial field as driving devices for various mechanical equipment such as fans, pumps, compressors, machine tools, and conveyor belts, making them the most energy-consuming equipment. According to statistical data, if the efficiency of industrial motors is increased by 1%, the annual electricity consumption savings will be equivalent to the annual electricity consumption of a medium-sized city in China, with huge energy-saving potential.

In the past 20 years, the Resources and Environment Research Branch of our institute, in collaboration with national regulatory departments, industries, and enterprises, has continuously improved the energy efficiency standards for electric motors in China, promoted the progress of energy-saving technology for electric motor products, and driven the improvement of the energy efficiency level of motor drive equipment such as compressors, water pumps, and fans. This has promoted the improvement of industry quality, efficiency, and green transformation, and achieved an overall improvement in the energy efficiency level of the entire equipment manufacturing industry.

01 International Standard - IEC60034:2016

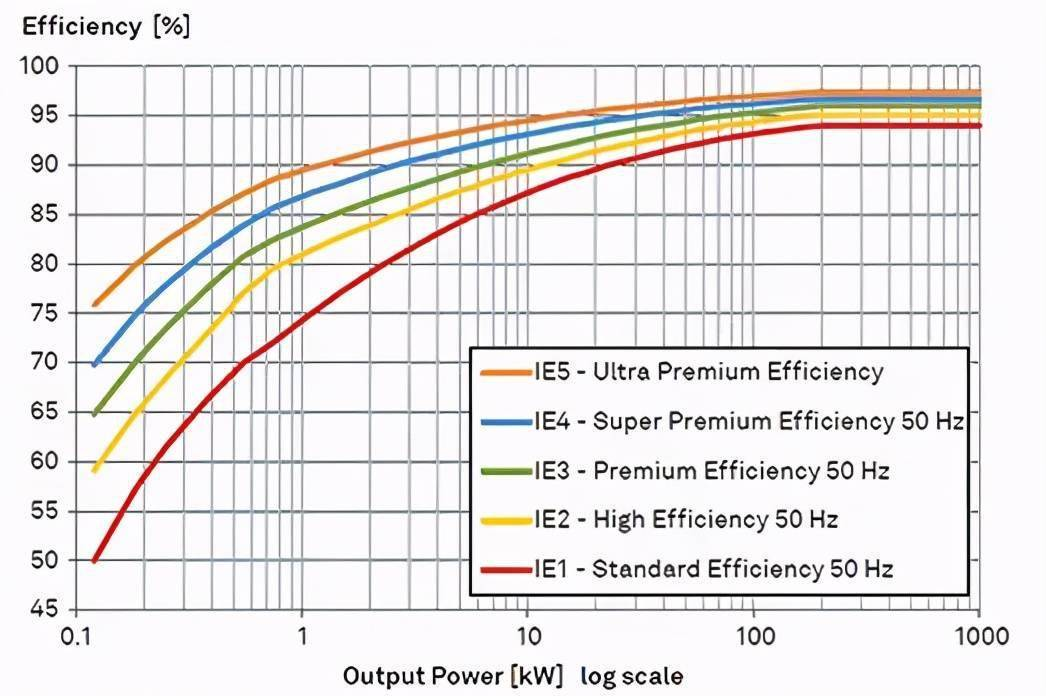

The International Electrotechnical Commission (IEC) issued the motor energy efficiency standard level IEC60034:2016 in 2016, in which IEC 60034 sets the motor energy efficiency standard as five levels (originally four levels), IE1, IE2, IE3, IE4 and IE5. The higher the efficiency, the higher the efficiency. IE5 is currently the highest efficiency level.

02 National Standard GB 18613-2020

In order to save energy and reduce emissions, China has taken multiple measures and vigorously produced and promoted high-efficiency motors. Enforce motor energy efficiency standards and promote motor energy efficiency labeling on national standards for motors.

In May 2020, China officially released the latest version of the mandatory national standard "Energy Efficiency Limits and Energy Efficiency Grades for Electric Motors" (GB 18613-2020), which was officially implemented on June 1, 2021.

In the GB 18613-2020 standard, IE5 efficiency is listed as the highest first level energy efficiency indicator for China's three-phase asynchronous motors, IE4 efficiency is the second level energy efficiency level for China's three-phase asynchronous motors, and IE3 efficiency is the third level energy efficiency level for China's three-phase asynchronous motors. This represents another level of improvement in the efficiency level of China's small and medium-sized three-phase asynchronous motors.

The comparison table between China and IEC energy efficiency standards is as follows:

IEC | GB18613-2020 National standard | GB18613-2012 National standard |

IE5 | GB Energy efficiency level 1 | |

IE4 | GB Energy efficiency level 2 | GB Energy efficiency level 1 |

IE3 | GB Energy efficiency level 3 | GB Energy efficiency level 2 |

IE2 | GB Energy efficiency level 3 |

As the largest end-use device with the highest electricity consumption, motors are widely used in fans, water pumps, compressors, transmission machinery, etc. Their electricity consumption accounts for over 60% of the total social electricity consumption. Among them, small three-phase asynchronous motors account for about 35% of the power consumption, making them a major consumer of electricity.

Therefore, developing high-efficiency electric motors in China is one of the important measures to improve energy utilization efficiency, which meets the development needs of China and is very necessary. The energy-saving engineering of motor systems is a key area of national energy conservation and emission reduction work.

Through the implementation of this standard, in accordance with the requirements of the "Motor Energy Efficiency Improvement Plan (2021-2023)" jointly issued by the Ministry of Industry and Information Technology and the State Administration of Market Regulation, by 2023, the proportion of high-efficiency and energy-saving motors in service (calculated based on a 3% energy efficiency improvement) will reach over 20%. The high-efficiency and energy-saving motor system (calculated based on a 20% system energy efficiency improvement) will achieve an annual energy saving of 326 billion kilowatt hours, equivalent to an annual energy saving of 100 million tons and a carbon dioxide emission reduction of 187 million tons.

Considering the driving force of the upstream raw material industry and the improvement of the management and usage level of downstream users, the release and implementation of this standard has significant economic and social significance.

JOY MACHINERY always adheres to the corporate vision of "building a leading brand of oil-free air compressors in the world", and hopes to provide high-quality, clean and safe air for food, beverage and other production enterprises on the road of oil-free air compressor research and development, production and sales. Source protection, and also contribute a little bit to people's health and safety.

JOY MACHINERY oil-free air compressor series is widely used in the food and beverage processing industry due to its clean air source and continuous and stable gas transmission. If you have any needs, please contact us! JOY Machinery (Shanghai) Co., Ltd. has a professional design team with rich experience and welcomes customization. Diversified products can meet most applications and meet your one-stop shopping needs. The air compressor series includes power frequency screw air compressors, variable frequency screw air compressors, permanent magnet variable frequency screw air compressors, two-stage compression screw air compressors, integrated screw air compressors, laser cutting air compressors, medium and high pressure air compressors. Air compressors, oil-free water-lubricated screw air compressors (special oil-free screw air compressors for the medical industry), diesel-moving screw air compressors, electric-moving screw air compressors and other products.

"Customer satisfaction is our unswerving pursuit", "High quality, good services", and strive to make every customer use the good products they like.

For more information about our products, please visit us at : www.wriol.cn, 24-hour hotline: 13621925718 (WeChat, WhatsApp).