JOY MACHINERY (SHANGHAI) CO.,LTD.

NORMAL TEMP WATER COOLED AIR DRYER

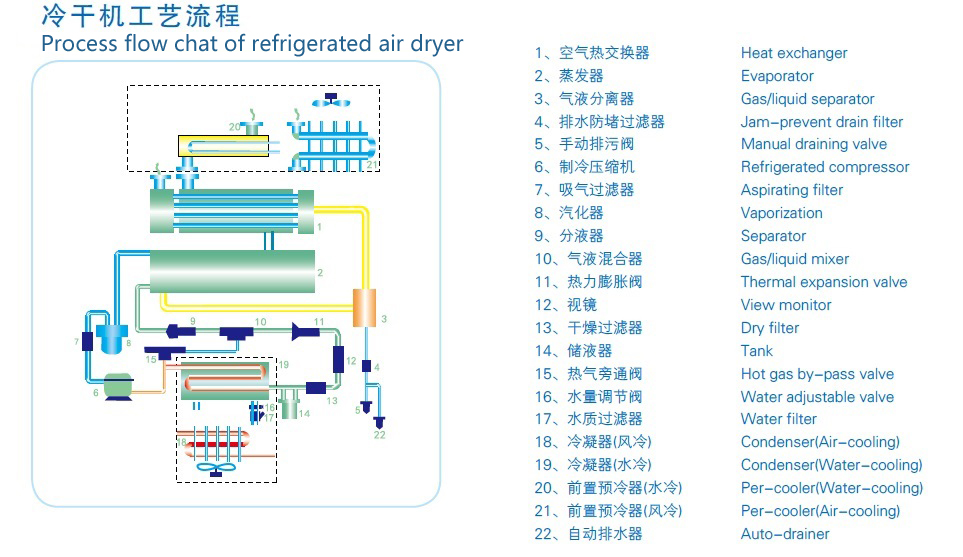

1. Flow chart

2. Working principle

The refrigerated air dryer is based on the principle of freezing and dehumidification, using a fully enclosed compression refrigeration system to cool down the compressed air discharged from the air compressor, so that a large amount of saturated water vapor and oil mist condensed droplets contained in it are passed through the gas and water. After separation, it is discharged by the automatic drain. The saturated compressed gas with higher temperature enters the pre-cooler of the refrigeration dryer, and exchanges heat with the dry and cold gas from the evaporator in the pre-cooler. Exchange, so that its temperature is reduced to close to the evaporation temperature of the refrigerant. During the two cooling processes, the water vapor in the compressed gas can be condensed into liquid water droplets and enter the gas-water separator with the airflow, and the separated liquid water is passed through the automatic drainer. Out of the machine, the dry compressed gas with a lower temperature enters the precooler, and exchanges heat with the wet saturated gas that has just entered, so that its temperature is increased, so that a lower water content (that is, a higher dew point) is obtained at the exhaust port of the cold dryer. low), dry compressed gas with low relative humidity. Refrigerated dryers have become the first choice for air compressor station purification equipment in various industries due to their reliable operation, convenient management and low operating costs.

3. Product feature

Refrigeration and air system, after accurate calculation, the design parameters are left with a margin of more than 20%.

The refrigeration compressor adopts the international advanced rotary or scroll, piston type hermetic refrigeration compressor and semi-hermetic screw refrigeration compressor (above 30HP), with stable operation, low noise, reliable performance, long power saving life, and energy efficiency ratio High, the protection level is IP54 (dust and splash proof).

The heat exchanger and air condenser are made of high-quality copper tubes with pure aluminum fins. The turbulent structure has high heat exchange efficiency, so it is small in size and compact in structure. The barrel material is made of stainless steel or carbon steel galvanized to avoid secondary pollution to the compressed air.

The refrigeration control components are all well-known refrigeration components with excellent performance. They have the functions of throttling and depressurization of the thermal expansion valve, the energy adjustment function of the hot gas bypass valve, and the functions of overcurrent, overload, and refrigerant high and low pressure protection.

The gas-liquid separator adopts the organic combination of cyclone separation and stainless steel wire mesh to capture mist, which has a complete gas-liquid separation effect, avoids the secondary evaporation of water, and ensures the drying effect of the cold dryer. It has better performance than a cyclone separator, and at the same time, it has a lower cost than a filtration gas-liquid separator, and has a higher performance-price ratio.

The water condenser is made of high-quality low-fin copper tubes, with slow water flow, multi-stroke, and high heat exchange efficiency, so it is not suitable for scaling in long-term use.

The automatic drainer can be set as needed, and the effect is good in addition to water removal and energy saving; floating ball type, electronic timing can be selected.

External rotor cooling fan, large air volume, low noise, frequent start and stop and long life.

The pressure-bearing components are manufactured, tested and accepted in accordance with the national GB150-1998 "Steel Pressure Vessel" and GB151-1999 "Shell and Tube Heat Exchanger", and are subject to the supervision of the "Pressure Vessel Safety Technical Supervision Regulations".

The equipment structure design is reasonable, easy to maintain.

The surface is thermally sprayed, with beautiful appearance and no rust.

No basic installation, stable operation without vibration, low maintenance rate, no consumables, low operating cost, and no need for special personnel to wait for continuous operation.

4. working conditions and technical indicators

Standard Working Condition | |

Cooling Way | Water-cooled |

Capacity | 11-300 m3/min |

Power(KW) | 2.5-60 |

Inlet air temperature | ≦80℃ (High TEMP type) |

Ambient temperature | ≦45℃ |

Pressure dew point | 2-10℃ |

Inlet air pressure | 0.4-1.3 Mpa |

Pressure drop | ≦3% of the working pressure |

Refrigerant | R22/R134A/R407C |

Cooling water Inlet pressure | 0.2-0.4 Mpa |

JOY MACHINERY (SHANGHAI) CO.,LTD.

NORMAL TEMP WATER COOLED AIR DRYER

The large-scale water-cooled unit adopts screw type refrigerant compressor, which has high cooling effect, stable operation, wide application range, and has a longer operating life than ordinary compressors under standard operating conditions. Adopt continuous stepless capacity adjustment system. It can do continuous control between 33% and 100% of the cooling capacity to achieve the function of stable output.

The continuous stepless capacity regulation system adopts the programmable controller and remote control system produced by SIEMENS, Germany, and takes the dew point temperature as the control benchmark. Due to the continuous stepless capacitance adjustment, not only the dew point temperature is constant to ensure the cooling effect, but also a lot of energy consumption can be saved. adverse effects.

Especially suitable for areas with abundant water resources.

█ The performance of the whole dryer is more stable

The eternal rotor fan is adopted, and the wind power is stronger, thereby improving the efficiency of condensation and pre-cooling, and making the operation of the whole air dryer more stable and reliable.

█ Better air environment

The heat exchange design is unique, the heat exchange efficiency is doubled, and a more superiorair environment is created.

█ High efficiency and long life

The core component compressor adopts well-known brands with better cooling effect and longer serice life.

█ Reasonable design and small footprint

Novel design, beautiful appearance, compact structure, small footprint, reasonable layout, easy to use and maintain.

JOY MACHINERY (SHANGHAI) CO.,LTD.

NORMAL TEMP WATER COOLED AIR DRYER PARAMETERS

Model | Air Capacity | Pressure | Voltage | Compressor Power | Cooled Water | Dimension (mm) | Outlet | Weight |

N.m3/min | Mpa | KW | m3/h | 長*寬*高 | KG | |||

JMAD-13HTW | 13.5 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 3.0 | 5 | 1125*625*1045 | G2 1/2” | 150 |

JMAD-15HTW | 15.5 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 3.1 | 6 | 1120*700*1230 | DN65 | 190 |

JMAD-20HTW | 22 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 4.5 | 7 | 1300*750*1230 | DN80 | 260 |

JMAD-25HTW | 25 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 5.3 | 9 | 1300*750*1230 | DN80 | 280 |

JMAD-30HTW | 35 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 6.9 | 11 | 1600*820*1520 | DN100 | 390 |

JMAD-40HTW | 45 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 9.2 | 15 | 1800*820*1560 | DN100 | 420 |

JMAD-50HTW | 55 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 11.2 | 20 | 1900*900*1570 | DN100 | 500 |

JMAD-60HTW | 65 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 14.0 | 22 | 1900*900*1570 | DN125 | 560 |

JMAD-80HTW | 85 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 18.0 | 25 | 2500*1000*1230 | DN125 | 680 |

JMAD-100HTW | 110 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 20.0 | 30 | 2800*1000*2100 | DN150 | 850 |

JMAD-150HTW | 160 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 30.0 | 40 | 3300*1750*2000 | DN200 | 1200 |

JMAD-200HTW | 210 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 37.0 | 50 | 3800*1750*2000 | DN200 | 1500 |

JMAD-300HTW | 300 | 0.2-1.0 | 380 V/3 Ph/50 Hz | 45.0 | 80 | 4000*2000*2000 | DN250 | 1800 |