JOY screw air compressor has the characteristic of low rotary speed, low noise and long service life. The maximum discharged pressure of the normal screw air compressor can reach 1.3Mpa, and the pressure of the medium pressure screw air compressor can reach 4.0Mpa, and the maximum discharged capacity can reach 125m3/min. It is widely used in metallurgy, machinery, chemical industry, geology and mining, electric power, clothing and so on.

Characteristic

1. Professional design, compact structure, small size.

2. Large discharged capacity, stable discharged pressure and the high efficiency.

3. Lower discharged temperature.

4. Safe and reliable, smooth operation, low noise, long maintenance cycle and service life.

5. The intelligent control system fully meets the needs of uninterrupted operation under unattended.

6. Multiple air compressors are on-line automation, automatic start / shutdown according to compressed air consumption, non-attended operation / shutdown.

7. A single air compressor can automatically adjusts the volume of air supply according to the compressed air consumption, and more energy-saving.

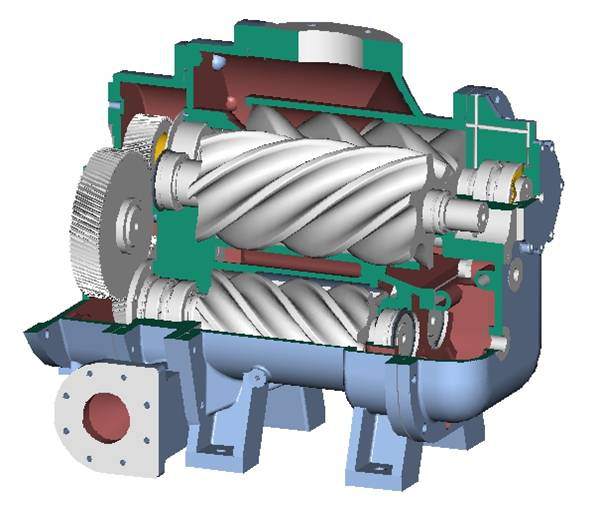

? World High End Screw Airend The world's top airend, high efficiency, low speed, the rotor with the third generation non-symmetrical 5: 6 tooth, the world's best profile design, the seal technology upgrade from line seal to belt seal, three layers of seals can ensure the airend no leakage, the discharge air can be increased by 5%-10% through optimizing the rotor internal structure. The diameter of the rotors is big and low rotary speed, low noise and long service life.. Processing by imported screw grinder, high precision, low energy consumption. |

|

?High quality, Efficient Motor The new generation of customized screw air compressor adopts advanced, efficient and energy-saving IP54 to protect the fully enclosed energy-saving motor, which can effectively prevent dust and water stains from entering the motor. By adjusting the relevant dimensions in the motor, the winding parameters of the motor are optimized, the imported high-efficiency materials are selected, and the control mode is improved. The average efficiency is increased by 1.9% at full load and the current is reduced by more than 8% at unloading. Equipped with high-performance imported SKF Bearing, protection grade IP54, insulation grade F. Low noise and long service life. |

|

?Energy-saving Air Intake Valve The high-quality and reliable air inlet valve is adopted to effectively control the loading and unloading of the unit. The lifting structure is adopted, which has no gap and can be completely sealed. There is no need for pneumatic control of the cylinder, sealing diaphragm and other vulnerable parts, so as to save energy consumption. Equipped with high-quality solenoid valve parts, it can effectively regulate the flow of loading, unloading and shutdown of the unit. |

|

?High efficient Cooler and Cooling System The axial flow fan is equipped with SKF heavy-duty bearing, with low speed, low noise and long service life. Lower exhaust temperature (5 ℃ - 15 ℃ higher than the ambient temperature) and wider environmental adaptability. The super large cooler volume design is adopted, leaving 30% allowance to improve the cooling efficiency, effectively prevent the high temperature of the machine, and the inner wall is treated with anti-corrosion treatment to adapt to worse working conditions and prolong the service life. Effectively reduce the high temperature phenomenon in the operation of the unit, the best oil temperature control and prolong the service time of 20% lubricating oil. |

|

?High Efficient Air Filter System Specially designed for the dust environment, it adopts the 2-stage high-efficiency separation mode of large air filter, centrifugation and filtration separation. The design of air inlet end is reasonable, axial phase air inlet, low pressure loss, reduce energy consumption, pressure loss and energy consumption, so as to ensure the normal and stable operation of the unit under complex working conditions. |

|

?High Efficient Oil Filter The integrated design scheme increases the oil separation core and improves the filtration effect. The oil content of the discharged compressed gas is low (less than 2ppm), which reduces the loss of lubricating oil, effectively protects the high-efficiency temperature operation of the equipment at the gas end, and improves the service life of the equipment. Large oil filter is adopted, which has high separation efficiency, ensures the cleanness of oil and prolongs the service life of lubricating oil and various parts inside the unit. |

|

?High Efficient Oil/Air Separator The high-efficiency oil-gas separator is adopted to control the residual oil in the exhaust below 3ppm through oil separation treatment in three stages: centrifugal separation, gravity separation and filtration separation. |

|

?High Efficient Control System Core electrical control components to ensure long-term stable and reliable operation of the unit. Professional wiring interface, reasonable, clear and convenient for maintenance. Automatic control, manual control, multi machine joint control and other control modes to improve work efficiency. It adopts new intelligent microcomputer control technology and PLC programmable control, which is simple and easy to understand and easy to operate. The whole machine control is composed of a fully automatic computer system, which adopts a new touch LCD. The operation status (Chinese / English) of the whole machine is displayed on the screen, and the parameter information such as exhaust pressure, exhaust temperature, current value, load status, operation time and frequency converter consumption current are displayed in real time. At the same time, it has self diagnosis function to display all-round safety protection measures such as maintenance, early warning and abnormal shutdown alarm in real time, To set or adjust the required parameters, just click your finger. The operation is more labor-saving and time-saving, making the daily inspection, maintenance and management easier. If equipped with RS485 communication interface, it can realize multi machine joint control and remote control functions, so as to achieve the best state of gas source management and system optimization, and make the screw air pressure more intelligent and energy-saving. |

|

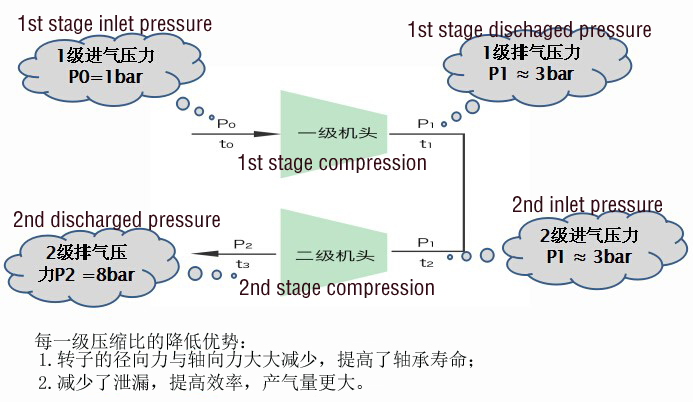

The value of two-stage compression compressor (2 factors to increase efficiency)

1. Volumetric efficiency is increased: the reduction of compression ratio for every stage reduces the internal and external leakage of each stage.

2. Isothermal compression process: sufficient interstage cooling process, oil and compressed air is fully mixed and cooled for the compressed air between the 1st stage discharge and 2nd stage suction position, effective cooling, so the second stage compression process close to isothermal compression.

Overall layout characteristics for the 2 stage compression

The main advantage of the two stage compression screw compressor is high energy efficiency, larger discharged capacity for the same power.

Compared with the single stage compression, the two stage compression is closer to the isothermal compression, more power saving, the two stage compression adopts the isobaric ratio to set the interstage pressure ratio, so the compression ratio of each stage is much lower than that of the single stage compression ratio. The reflux leakage between the rotors is greatly reduced, the volume efficiency and the adiabatic efficiency greatly improves too and the generated discharged air delivery is more correspondingly.

In principle, two stage compression saves 5 to 10% energy than that of the single stage compression.

|  |

Application scope of piston air compressor, air compressor and screw air compressor | |

Air compressors are one kind of common power equipment. In simple terms, it is a device that compresses air to generate potential energy. Therefore, it has a wide range of applications. The common applications mainly include the following industries: | |

Mine | Air for ventilation, drilling large holes, removing water with compressed air, filtering fines, pneumatic hoist, driving rock drilling rigs, pneumatic drilling, blowing holes, piling machines, rock drilling machines, etc. |

Factory | Air jet cleaning, driven tools (steam hammers, concrete shakers, drills, grinders, cranes, paving breakers, riveting guns, descaling, pipe reels, wrenches), sandblasting, metallization, painting, water spray systems |

Sheet metal | Stirring solutions, transporting chips, jet cleaning, driving packaging presses, driving platen chuck clutches and positioners, air tools, finishing hammers, air picks, drills, grinders, hoists and lifters, combination tools, riveters, Sand blasting, lubricant spraying, paint spraying, container leak detection |

Forging | Blown oxide surface, furnace door air curtain, hoist and lift, drive bending and straightening machine, drive clutch brake and clamping device, drive forging hammer, fuel burner |

Casting | Hot metal truck positioning, cleaning equipment, conveying sand, driving pneumatic tools, sanding machines, grinding machines, hoists and lifts, air picks, tamping machines, steel brushes, sandblasting, sand screening, mud blasting cores |

Quarry | Lifting and handling materials, rock drilling rigs, gas supply, drilling and blasting machines, rock drilling machines, hand drills, water pumps |

Rubber industry | Cleaning of moulds and machinery, air lift, demolding, mould opening, pneumatic control, spraying |

Textile industry | Mixing liquids, air lifts, wetting, running accumulators, spraying liquids, spraying systems, infusions |

Chemical fiber | Gas for instrumentation, gas for silk suction gun and power source for printing and dyeing, etc. |

Cement | Storage ventilation, cement slurry mixing, cement bag cleaning and sealing, raw material mixing, dump truck, cleaning equipment, clinker cooling, cement and coal conveying, cement kiln cleaning, vehicle and ship loading and unloading, lifting and hoisting, pneumatic control |

Chemical | Aeration and agitation, separation tower gas, cleaning equipment, combustion gas, conveying, lifting liquid, spraying, cleaning pipeline, pneumatic control, process gas, conveying liquid |

Thermal power | Instrumentation, desulfurization and denitrification, blowing and cleaning pipes, bag dust removal, blowing off soot, cleaning boiler and condenser pipes, jet cleaning, transferring pulverized coal, removing sewage, pneumatic control, auxiliary equipment control, coal-fired transportation, industrial Water treatment equipment, etc. |

Hydropower | Engine control, lock maintenance, drive controller, drive lubrication pump, drive lock, start control, cleaning garbage net |

Beverage | Bottle washing machines, canning machines, interior spraying of wine barrels, gas for the food industry |

Food | Stirring liquid, gas (oxygen) for fermentation tank, cleaning equipment with nozzle, cleaning container with nozzle, material conveying, material filling, fermentation, food dehydration, filtration |

Glass industry | Blowing bottles and glassware, blowing lamps and electron tubes, supporting combustion of glass liquid, transferring raw materials, glass etching, clearing and drilling, conveying glass, pneumatic control, vacuum hanging plate, purging of residual material in the oil gun, cooling and cooling of the gun body, Bag dust removal and filter cartridge backflushing. |

Steel | Stirring solution, gas for deoxidation, gas for high-level converter, positioning of charging car, drilling of sediment chamber, unloading bag, cleaning of open-hearth furnace flue, driving clutch and brake, driving furnace door, driving charging and conveying device, driving lubrication system, Drives pneumatic tools, picks, grinders, hoists and lifts, sandblasting, blast furnace blasting, vacuum degassing |

Wood and furniture | Jet cleaning, air hoisting, impregnated wood, bending and straightening, clamping and clamping, pneumatic tools, engraving tools, drilling rigs, polishing machines, sanding machines, sandblasting, painting, water spraying |

Refinery | Combustion gases, draining and cleaning oil circuits, hoisting and hoisting, drive control systems, catalyst recirculation, sandblasting, painting |

Paper | Air cleaning equipment, hoists and lifts, pool anti-icing, roll feeding, pressed paper products, drive clutches, drive paper breakers, feed through machines, pneumatic controls, head case pressurization, head case removal, waste paper removal , vacuum drying |

Pharmaceutical | Stirring liquids, gas (oxygen) for fermentation of antibiotics, conveying raw materials, mixing and stirring raw materials, driving centrifuges, pneumatic control, jet pulverization, spray drying, transferring liquids, vacuum drying, vaporization and instrument gas |

Plastic | Cleaning of jet equipment, casting blanks, inflation of air objects for molding, inflation into tubes during extrusion, vacuum or pressure molding, cylinder operation |

Printing | Stir the solution, pack paper, lift |

Injection mold | Air assisted injection molding |

Metallurgical | Metal smelting, sintering, cold rolling, hot rolling, bundling and packaging of wire rods and sheets, production lines for continuous casting and rolling, etc. |

3D printing | Base room waste heat, particle, powder purge |

Military | Packaging of explosives, automatic control devices of torpedoes, automation equipment of ships, equipment purging, instrument gas, power execution and other operations. |

Tobacco | It is also used in power execution equipment such as wire injection machines, cigarette rolls, splicing and packaging, as well as instruments and equipment cleaning. |

Medical chamber | Supply and exhaust (oxygen) systems for air pressurized chambers and pure oxygen pressurized chambers |

Automobile | Spray Washing Machines, Drive Assembly Tools, Lifting, Pneumatic Controls, Tire Inflation, Forging Shops, Foundry Shops, Sheet Metal Shops |

Aircraft | Blasting machines, stripping, driving assembly tools, drilling rigs, steam hammers, hoists, combination tools, reamers, riveting guns, screwdrivers, forging hammers, metal forming presses, sandblasting, painting |

Aerospace | The rocket is purged with high-pressure nitrogen, and the oil-free high-pressure chamber is purged. In the aerospace industry, in addition to being able to withstand irradiation and high temperature, pneumatic devices can also withstand large acceleration speeds, so they have been widely used in the control of modern aircraft, rockets and missiles. |

Model | Air Capacity | Pressure | Power | Noise | Dimension | Outlet | Weight | |

N.m3/min | Mpa | KW | HP | DB | L*W*H, mm | KG | ||

JM-15AII | 3.0 | 0.7 | 15 | 20 | 68±2 | 1500*1000*1330 | G1 1/2” | 1100 |

2.9 | 0.8 | |||||||

2.4 | 1.0 | |||||||

2.2 | 1.3 | |||||||

JM-18.5AII | 3.6 | 0.7 | 18.5 | 25 | 68±2 | 1500*1000*1330 | G1 1/2” | 1100 |

3.5 | 0.8 | |||||||

2.9 | 1.0 | |||||||

2.5 | 1.3 | |||||||

JM-22AII | 4.2 | 0.7 | 22 | 30 | 68±2 | 1500*1000*1330 | G1 1/2” | 1100 |

4.1 | 0.8 | |||||||

3.5 | 1.0 | |||||||

3.2 | 1.3 | |||||||

JM-30AII | 6.5 | 0.7 | 30 | 40 | 68±2 | 1900*1250*1570 | G2” | 1900 |

6.4 | 0.8 | |||||||

4.9 | 1.0 | |||||||

4.1 | 1.3 | |||||||

JM-37AII | 7.2 | 0.7 | 37 | 50 | 68±2 | 1900*1250*1570 | G2” | 1900 |

7.1 | 0.8 | |||||||

6.3 | 1.0 | |||||||

5.4 | 1.3 | |||||||

JM-45AII | 9.8 | 0.7 | 45 | 60 | 72±2 | 1900*1250*1570 | G2“ | 1900 |

9.7 | 0.8 | |||||||

7.8 | 1.0 | |||||||

6.5 | 1.3 | |||||||

JM-55AII | 12.8 | 0.7 | 55 | 75 | 72±2 | 2500*1470*1840 | G2 1/2” | 3300 |

12.5 | 0.8 | |||||||

9.6 | 1.0 | |||||||

8.6 | 1.3 | |||||||

JM-75AII | 17.5 | 0.7 | 75 | 100 | 72±2 | 2500*1470*1840 | G2 1/2” | 3300 |

16.5 | 0.8 | |||||||

12.5 | 1.0 | |||||||

11.2 | 1.3 | |||||||

JM-90AII | 20.8 | 0.7 | 90 | 125 | 72±2 | 3150*1980*2150 | DN80 | 4100 |

19.8 | 0.8 | |||||||

17.9 | 1.0 | |||||||

14.3 | 1.3 | |||||||

JM-110AII | 24.5 | 0.7 | 110 | 150 | 72±2 | 3150*1980*2150 | DN80 | 4200 |

23.5 | 0.8 | |||||||

19.7 | 1.0 | |||||||

17.6 | 1.3 | |||||||

JM-132AII | 30.0 | 0.7 | 132 | 180 | 72±2 | 3150*1980*2150 | DN80 | 4300 |

28.0 | 0.8 | |||||||

23.5 | 1.0 | |||||||

19.8 | 1.3 | |||||||

JM-160AII | 34.5 | 0.7 | 160 | 220 | 75±2 | 3150*1980*2150 | DN100 | 5350 |

33.6 | 0.8 | |||||||

30.0 | 1.0 | |||||||

23.8 | 1.3 | |||||||

JM-185AII | 41.0 | 0.7 | 185 | 250 | 75±2 | 3800*1980*2150 | DN100 | 5450 |

38.4 | 0.8 | |||||||

32.5 | 1.0 | |||||||

28.6 | 1.3 | |||||||

JM-200AII | 44.6 | 0.7 | 220 | 300 | 75±2 | 3800*1980*2150 | DN100 | 5600 |

43.0 | 0.8 | |||||||

38.5 | 1.0 | |||||||

32.8 | 1.3 | |||||||

JM-220AII | 48.6 | 0.7 | 220 | 300 | 82±2 | 3800*1980*2150 | DN125 | 6500 |

47.0 | 0.8 | |||||||

41.0 | 1.0 | |||||||

38.0 | 1.3 | |||||||

JM-250AII | 55.0 | 0.7 | 250 | 350 | 82±2 | 3800*1980*2150 | DN125 | 6600 |

54.0 | 0.8 | |||||||

46.0 | 1.0 | |||||||

40.0 | 1.3 | |||||||

JM-280AII | 61.0 | 0.7 | 280 | 375 | 82±2 | 4000*2300*2250 | DN100 | 6340 |

59.9 | 0.8 | |||||||

51.0 | 1.0 | |||||||

44.9 | 1.3 | |||||||

JM-315AII | 69.0 | 0.7 | 315 | 420 | 82±2 | 3750*2400*2350 | DN125 | 6850 |

67.6 | 0.8 | |||||||

61.0 | 1.0 | |||||||

51.0 | 1.3 | |||||||